The clock's ticking on fall food plots, and that's precisely when tractors and implements seem to break down. These tips will keep your equipment up and running when you need it most

It had been a hot, dry summer. August was drawing to a close and we needed to get our fall food plots in. The forecast was promising. The remnants of a hurricane were set to pass over our farm in central Kentucky with slow, soaking rains for the next three days. It was the perfect day to get some seed down. That made standing in our food plot watching hydraulic oil spew from a busted hose about as frustrating as it gets.

Spend time around farm equipment and you know breakdowns are inevitable. If a part moves, and sometimes even if it doesn't, it's going to break eventually. Those breakdowns always seem to come at the worst time. But routine maintenance will minimize the downtime and keep your equipment in top working order.

Byron Snow, branch manager at SunSouth Equipment in Columbus, Georgia, says maintenance is the key to longer equipment life and reliability. Annual routine services teamed with daily inspections will keep you in the woods working and not waiting for repairs, he says.

Steve Sea and his son Jacob own County Equipment Company near our Kentucky farm. Over the years, they have seen just about every kind of equipment breakdown imaginable. Steve offers these maintenance tips to keep equipment working when you need it.

(Ride in style this season: Realtree Camo UTV Kit)

Familiarize Yourself

Read the owner's manual and learn where all the parts are located, Steve says. You would be amazed at how hidden some important grease fittings are on some of this stuff. If you didn't read the manual to know where they were, you could go the entire life of the equipment and never grease the fitting.

Snow echos that advice. The manual is going to have a list of preventive maintenance tasks that need to be performed at a set number of hours, he says. Not doing these maintenance tasks when they are recommended is a sure way to end up with a breakdown.

Another tip? Keep your equipment clean. Don't put stuff away caked in mud and dirt. That's hard on parts and makes repairs that much tougher.

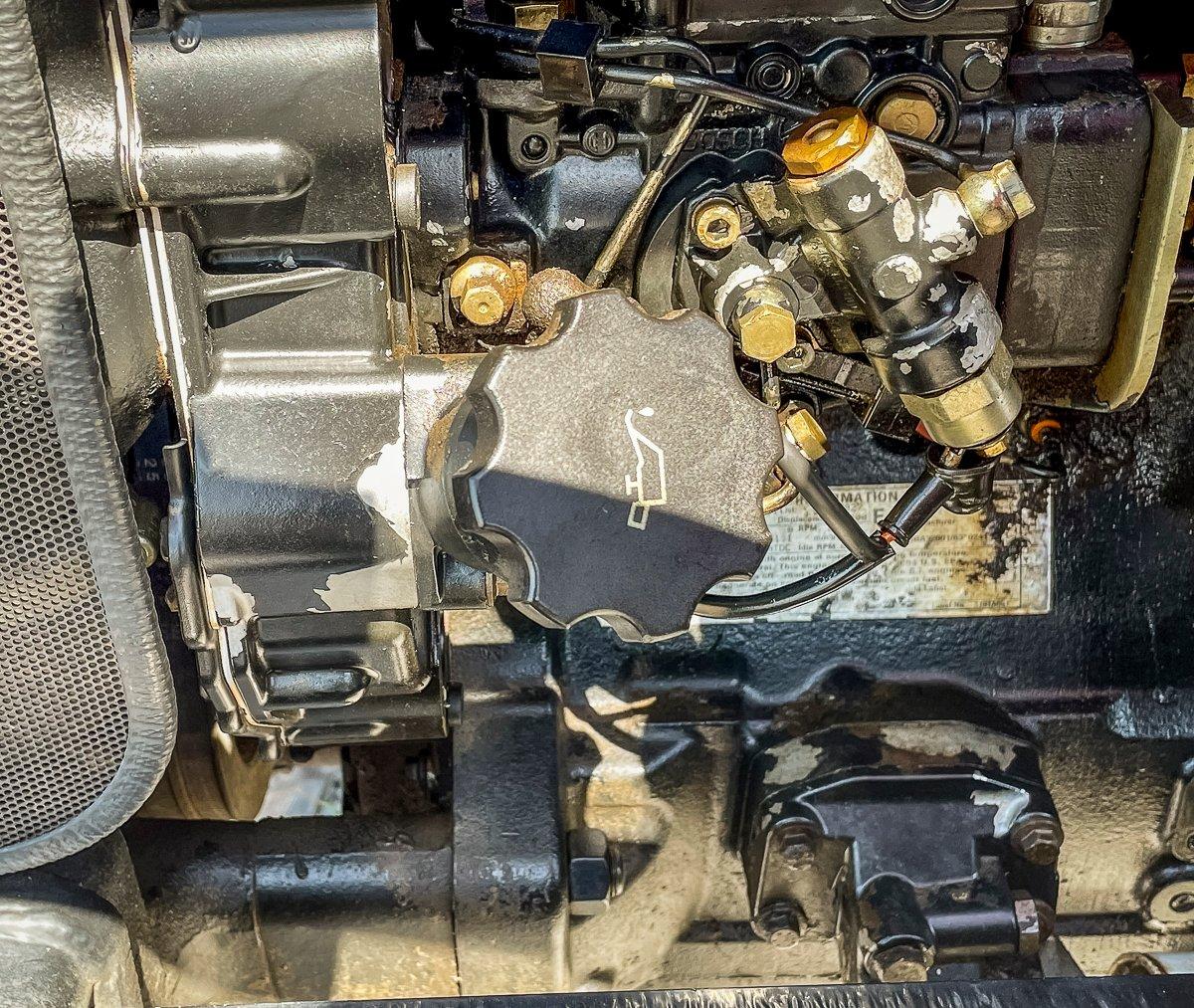

Tractors

A reliable tractor is essential for land management. Most hunters don't use their equipment as much as full-time farmers, so they can probably get by with once-a-year oil and filter changes, Steve says. But that doesn't mean you can go a year without checking fluid levels. Check your oil and other fluid levels on a regular basis and top them off if they need it. Those fluid checks should include coolant levels in the radiator, as well as hydraulic and oil levels in gear boxes as well.

Snow adds fuel to the list of fluids to check regularly. We always suggest fresh fuel and full tanks for tractors and other equipment, he says. Treat all fuels with conditioners and additives to stabilize and disperse any water. Top off all fuel tanks after running to minimize air space for moisture condensation, and ensure you are ready to go to work when you need to.

-

Belts

Inspect the belts on your tractor on a regular basis. Once they start getting worn, frayed or dry rotted, it might be time to replace them, or at least buy a spare to keep on hand for when the old belt finally breaks.

-

Tires

Check your tires regularly and keep the pressure at the recommended level. Inspect for dry rot or anything that might be poking into the tire that will cause an air leak.

-

Radiator

We see a lot tractors come in running hot, Steve says. Most often, that is caused by a radiator full of plant debris, especially in the fall when folks are mowing. The best way to clean a radiator is to flush it out by spraying water or air through it from the back side toward the front. Be careful not to use really high water pressure, or you can bend the fins inside the radiator; a standard water hose spray nozzle usually works. And especially on larger, newer tractors, there will be a smaller condenser unit just in front of the main radiator. These get clogged, too, and the space between the two is really bad about filling up with seeds, plant debris and the like. Sometimes it looks like a piece of carpet has been wedged between the condenser and the main radiator. You want to make sure to clean those out as well.

-

Hoses

A busted hydraulic hose will leave you stranded every time. Inspect hoses for areas of dry rot or cracking, which are signs that the hose might be getting weak. Steve says that storing your equipment inside or covered whenever possible helps extend the life of hydraulic hoses, which tend to break down in the sunlight.

Implement Maintenance

-

Seed Drills

A good seed drill is worth its weight in gold when it comes to food plots. A drill will just about pay for itself over time with the seed savings verses broadcasting. You usually get much better seed-to-soil contact, plant spacing, and germination rates when using a drill as well. County Equipment specializes in the restoration and rebuilding small seed drills for hunters all over the country and offer these tips to keep your drill in top condition.

First, never leave seed in the hopper when you finish planting, Steve says. This attracts mice, which will chew holes through your hoses or plastic hopper parts to get at the seed."

At SunSouth, Snow even goes as far as putting a rodent repellent like Animal Stopper around the equipment. Besides leftover seed, varmints love to eat wire, insulation, hoses, seat belts, and steering wheels, he says. Seed also tends to swell when it gets wet, and that can clog the feeder tubes and make getting everything cleaned out take a lot longer than it needs to.

Steve says one of the best things you can do when operating a seed drill is to always raise your pans and plows at the end of a row before making a turn. Turning with your pans in the ground puts a lot of sideways strain on the bearings, something they aren't designed to take, and that wears them out a lot faster, he says.

General maintenance on drills includes keeping gear boxes lubed and all bolts tightened, grease fittings lubed, and replacing any lost seed tubes that might have fallen off in use.

-

Mowers

Often known generically by the brand name Bush Hog, rotary cutters are almost a necessity for good food plot installation and maintenance. Steve Sea offers these tips to keep your mowers working.

First, keep the blades sharp. They don't need to be shaving sharp like a knife, but they do need a decent edge, he says. Dull blades tend to pull weeds up by the roots instead of cutting them cleanly.

Next, keep the bolts tight on the gear box. Mower vibrations often shake gear box bolts loose, and a gear box that is shaking won't last long. Check the owner's manual for the correct lubrication. Many of the new mowers use a thin grease in the gear box instead of a heavy-duty oil, and it must be maintained at the correct level.

Keep implement drive shafts clean and lubricated so they slide and connect to the tractor PTO easily. Always locate all grease fittings and keep them lubricated regularly.

-

Discs and Cultipackers

The good things about discs and cultipackers is that there isn't a lot to go wrong. Steve says to keep bearings lubed and replace any bent or damaged pans for optimum performance. Snow recommends regularly inspecting frames for any small cracks and having them welded or otherwise repaired, then primed and painted to prevent rust.

Keep a Repair Kit

Even with the best maintenance, stuff is going to break down eventually. I like to keep a well-stocked tool box with me when we are working at the farm to keep a minor breakdown from ruining an entire day.

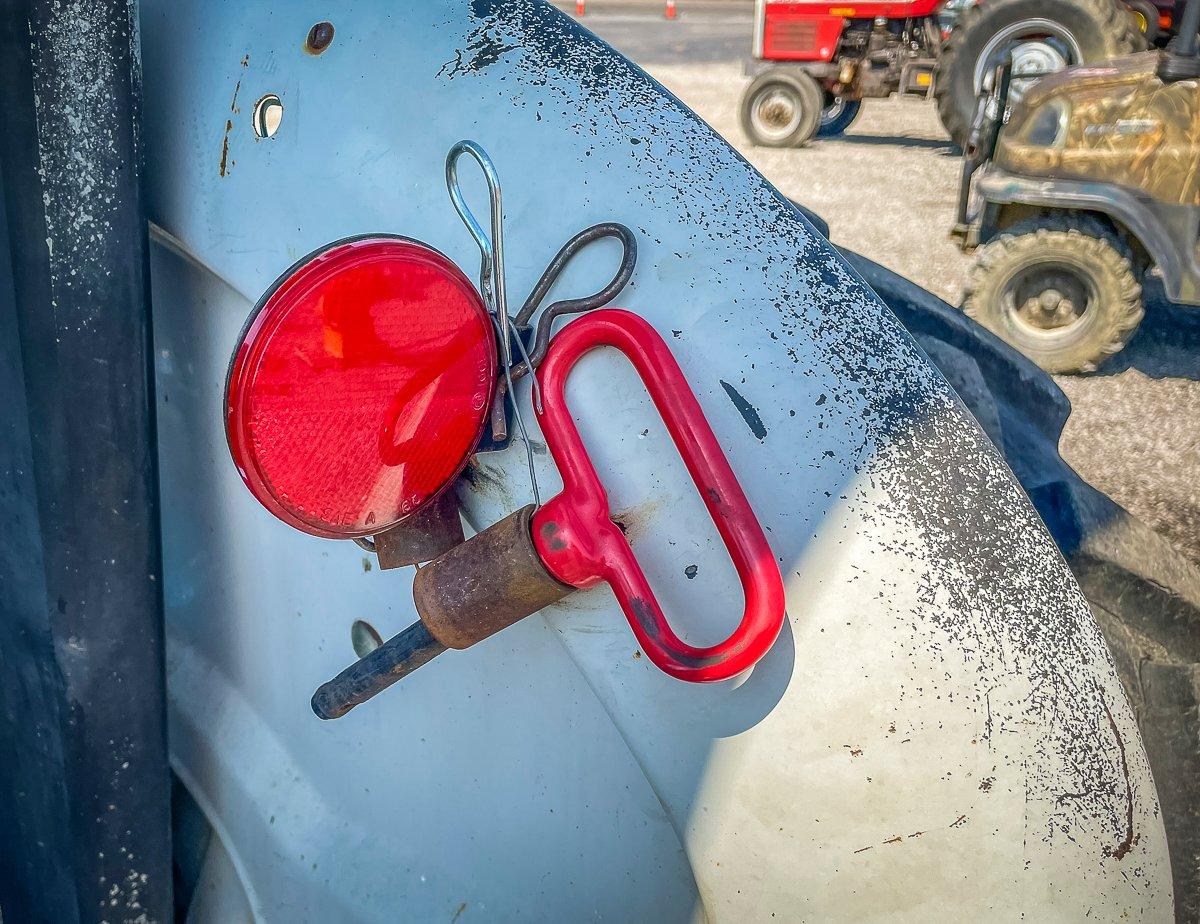

Besides tools, it's hard to go wrong with the redneck repair staples of duct tape, baling wire and WD-40, all useful in a myriad of ways when it comes to tractors and equipment.

Keep several spare hitch pins, cotter pins, etc. handy so you can quickly replace the ones that inevitably disappear while you're working. Spare belts to fit your tractor, mower or anything else with a belt can mean the difference in a quick repair verses a long trip to town. An air compressor that runs off my truck's DC power, plus a jug of green slime and a plug kit for tire repair have saved the day more than once.

All equipment will need repairs from time to time, but keeping up with maintenance between uses will breakdowns and the frustration that goes with them to a minimum, and ensure your equipment is ready to go when you're ready to plant those plots.